The Partnership with Tilsatec

Unipres were initially going through a high volume of gloves, resulting in high wastage and costs.

They were looking to prevent hand and arm injuries from cuts and abrasions whilst reducing the annual usage of gloves and ideally consolidating glove styles.

Tilsatec engaged with various decision-makers at Unipres , conducted a thorough review of the existing hand protection program and evaluated all applications and tasks undertaken in each Department. This is an important step in the process and provides the opportunity for Tilsatec to speak with staff, understand their pain points and how we can encourage consistent glove use on the factory floor.

Driving factor to change hand protection supplier?

“Gloves with high cut resistance, exceptional performance, and reliable protection at an affordable price point. We’ll work with the manufacturer to ensure our team can perform effectively”. Health & Safety Manager, Unipres

Understanding Departmental Needs

To ensure optimal hand protection across Unipres, we conducted comprehensive assessments of each department’s specific requirements. Site surveys and extensive glove trials were implemented to evaluate glove performance, monitor usage and how long the gloves were lasting, gathering direct feedback from all teams.

The 50-6121 cut level F foam nitrile coated 10 gauge glove provides maximum cut protection. Used across Die Maintenance, Press and Stamping for handling sharp parts and panels.

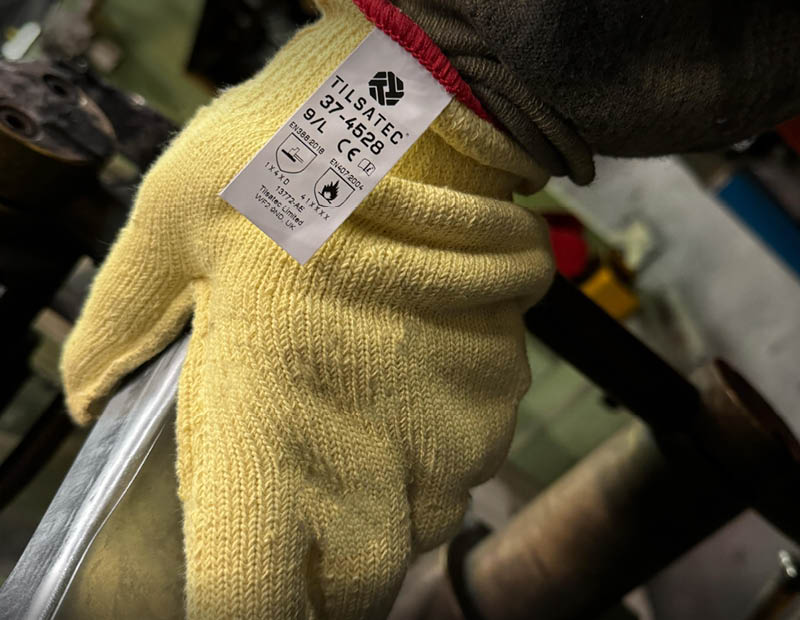

37-4528 – X-Heavy cut level D aramid knit glove

37-4528 is a robust, reliable extra-heavyweight aramid glove designed to provide level D cut protection combined with EN407:2020 contact heat and limited flame spread protection. Used in Assembly and Welding this glove provides cushioning for handling large heavy panels and body parts whilst giving protection when weld spatter and sparks may be present.

81-6121CV – Medium weight cut level F cool touch sleeve

81-6121CV is a cool touch seamless knit sleeve delivering maximum level F cut protection. Worn in conjunction with the 50-6121, the sleeve provides extended cut protection to the wrist and forearm when handling and moving sharp pressed metal parts and components.

84-3520 – 20” flame retardant cut level E sleeve with thumb slot

84-3520 is a cut level E FR sleeve worn throughout many departments at Unipres including Pressing, Stamping, Assembly and Welding. Inherently flame retardant it ensures arms as well as hands are not at risk from weld spatter or sparks.

18 Years of Trusted Partnership

Throughout the partnership, Tilsatec has closely collaborated with Unipres’ Health and Safety teams and plant workers to understand their key challenges and protection requirements in each department. This close collaboration has allowed Tilsatec to provide solutions that adapt to the ever-changing technology landscape within the industry.

This case study exemplifies the power of collaboration, working hand-in-hand with Unipres to deliver a sustained safety up, cost down hand protection program for nearly 2 decades.

Get in touch with our team today to see how we could implement a hand protection assessment for your business.