The Hidden Costs of Poorly Fitted Gloves

It may seem like a minor detail, but the fit of a glove can be the difference between a safe workday and a life-altering injury. Beyond the obvious discomfort, ill-fitting gloves compromise dexterity, grip, and ultimately, the very protection they are meant to provide. The dangerous notion of a ‘one-size-fits-all’ approach is repeatedly invalidated by real world data and field experience.

A compelling illustration of this comes from a recent survey conducted by the Women’s Engineering Society Out of 1,500 female workers, the results starkly revealed that PPE is still predominantly designed for male body types: 60% of men reported comfortable or perfectly fitting PPE, while a mere 26% of women could say the same.

This issue isn’t confined to a single sector; These but is prevalent across manufacturing, construction, rail, automotive, and glass industries. As workforces become increasingly diverse, providing inclusive sizing in hand protection is not just imperative for safety, but also for fostering an unbiased and efficient working environment. When PPE doesn’t fit, it not only escalates personal risk but also compels workers to dangerously modify their protection, hindering their ability to perform their roles effectively and efficiently, potentially resulting in the gloves not being compliant with EN standards.

Industry Insights into the challenges of ill-fitting gloves

Varying industries present unique hand protection demands, each bringing its own set of challenges when gloves don’t fit correctly. By understanding how the characteristics and fit of hand protection can have an impact on worker safety and performance, you can eliminate many unnecessary hazards and potential injuries.Cut Resistant Gloves

Cut resistant gloves are considered essential protection for workers across manufacturing, metal fabrication, and waste management, where they are frequently handling sharp objects. Yet, the sheer volume of options on the market doesn’t guarantee effective protection if sizing is overlooked.

Impact of Incorrect Sizing & Other Factors:

- Reduced grip: Gloves that are loose fitting can wrinkle and create an unusable grip on the equipment, tools and other materials which can increase the likelihood of slippage or contact with equipment that is potentially dangerous.

- Snagging hazard: Excess material can easily get snagged or caught on materials or equipment which can pull a worker’s hand into a hazardous situation.

- Compromised dexterity for precision tasks: There are many tasks in various industries which involve sharp objects or working with intricate nuts and bolts. Heavy duty gloves or ill-fitting gloves can have a significant impact on dexterity with reduced feeling and control

- Inadequate protection: Cut resistance can be compromised if the glove is stretched due to being small on the hand Resulting in non-compliance

At Tilsatec, we are committed to providing precision, comfort and protection. Understanding that every hand is unique, our Comfort+ series of cut resistant gloves represents a significant step forward in offering truly size-inclusive options. This extensive range comprises 13 distinct gloves, meticulously designed to ensure a comfortable fit and feel, making them for. Sized from 5 to 12, and available in gauges 13 to 18, Comfort+ gloves provide exceptional tactility and comfort, with a second skin feel.

Discover how the perfect fit of our Comfort+ series can upgrade your hand protection

Electrical Gloves

Gloves that are required for working within environments with equipment involving electrical current or live wires are classified as Category III Personal Protective Equipment. When working with such hazardous equipment, the margin for error should be zero.

Electrical Insulating Gloves are classified as Category III Personal Protective Equipment, covered by Module D of the PPE Regulation (EU) 2016/425. This means there is a mortal risk to life and it is a high risk environment.

- Reduced insulation protection: Rubber insulating gloves must remain intact and uncompromised to be fit for purpose. A glove that is fitted too tightly can become stressed leading to thinning of the material, resulting in compromised protection. impair

- Compromised grip: In situations such as If gloves aren’t not a good fit, they can significantly reduce the ability of the end user to perform the task, lead to a reduction of grip, and increase the risk of accidental contact with live components, resulting in shocks or, even, an arc flash.

- Damage to the Outer Protector Gloves: Electrical insulating gloves typically require a leather protector glove to be worn over them to prevent mechanical damage. If the leather protector glove or the inner insulating glove doesn’t fit correctly, this can lead to tearing and punctures electrical current exposure.

The Tilsatec Pulse® range is certified as Category III Personal Protective Equipment and tested according to ASTM D120, EN60903 and IEC EN60903. Category III products are these electrically insulating gloves include protection against both high and low voltage applications, as well as sizing options from 7-12 for Classes 00, 0, 1, 2 and 3, and 8 to 12 for Class 4 gloves.

As well as multiple sizing options, the gloves are ergonomically designed to reduce hand fatigue. Within this range, Tilsatec also offers leather protector over gloves designed specifically to complement and protect the inner insulating glove.

Explore the full Tilsatec Pulse range and find the right electrical hand protection solution for your needs.

Impact Gloves

In heavy duty industries such as oil and gas, manufacturing, construction and mining, workers are exposed to significant risks of impact injuries from falling objects, striking against surfaces or operating powered tools. Impact gloves are designed to mitigate these forces.

Impact of Incorrect Sizing & Other Factors:

- Misaligned Protection: The protective barrier on the impact glove is strategically placed at key areas that are more likely to receive impact and absorb the force; this is over the knuckles, fingers, and back of the hand. If the glove is too large for the wearer, the padding can shift, leaving vulnerable areas exposed and at high risk. If the glove is too small, the padding can be stretched or compressed, which can reduce its overall objective and effectiveness.

- Reduced Dexterity and Pinch Points: If impact gloves are ill-fitting or bulky, this can restrict hand movement, making it harder to grip equipment and tools used by the wearer, rendering the person unable to effectively do their job, leading to dropped tools or hands being inadvertently placed in pinch points.

- Hand Fatigue: The additional weight of impact gloves, whether from the materials used or the protective barrier, while offering protection, could make the gloves heavier. This can cause rapid hand fatigue, leading to a loss in grip strength when handling objects, and increasing the likelihood of an accident.

Our award-winning Collide-x series represents the pinnacle of impact protection, engineered to overcome the common challenges of bulk and restricted movement associated with traditional impact gloves. We are committed to ensuring uncompromised safety without sacrificing comfort or dexterity. Our Collide-x gloves feature the thinnest 6mm level 3 bumper on the back of the hand, designed by brand partner Koroyd. This advanced protective structure provides a higher level, two step damage control system that absorbs and disperses force while maintaining a remarkably low profile and flexibility.

Tilsatec Collide-x gloves feature lighter liner gauges, which ensure a comfortable, all-day wear experience, significantly reducing hand fatigue. We also offer an extensive size range from 7 through to 12 for our coated gloves, ensuring maximum dexterity whilst the protective layers maintain their integrity and positioning.

For heavy duty tasks and specific applications, our Collide-x mechanics and leather gloves extend inclusive sizing even further, available from size 7 all the way up to 13. This meticulous attention to fit ensures a snug, secure fit that prevents slippage and keeps impact protection precisely aligned with the hand’s anatomy, delivering truly reliable performance. To find out more about the Collide-x range, click here.

Chemical Gloves

There are many industries requiring chemical protection such as those handling hazardous waste, oil and other chemicals. Exposure to chemicals can cause serious skin damage impairing a workers ability to do their job and can potentially scar them for life. Chemical hand protection’s effectiveness depends entirely on the correct selection and fit of the glove.

Impact of Incorrect Sizing & Other Factors:

- Permeation and Degradation: It’s important when selecting hand protection for chemical use to choose those composed with the correct materials that can offer specific chemical resistance. This is imperative as it can protect against serious exposure to chemicals that may cause harm to the end user. It is also crucial to ensure that the glove is not used beyond its recommended breakthrough time as some chemicals can quickly degrade certain glove materials rendering them ineffective within seconds.

- Compromised barrier protection: If a glove that is chosen is too large, it can bunch together or create folds in which make it much easier for chemicals to seep through and make contact with the skin. On the same level that a small fitting glove can become stretched which potentially thins out the level of coverage, accelerating permeation or potentially causing rips and tears especially at the seams and between the fingertips.

- Reduction of Dexterity and Grip: When handling delicate chemical apparatus like glass tubes or thermometers, oversized gloves can have a significant impact on tactility, affecting fine motor skills. Oversized gloves can be cumbersome and can increase the risk of an accident. As much as an oversized glove can have an impact, a glove that fits on the smaller size can feel tight, restrict blood flow and cause hand fatigue and can lead to accidents and reduction of control of actions.

To address the complex demands of chemical handling with uncompromised safety, our high-performance chemical resistant gauntlet solutions are engineered not only for chemical protection but also to ensure a secure and ergonomic fit. The Tilsatec Chemical Resistant Gauntlets, featuring the proprietary RhinoYarn® technology, provide exceptional cut resistance alongside chemical protection. Available in various sizes and with advanced coatings, these gloves are designed to offer optimal dexterity and comfort, reducing the risk of chemical permeation and improving grip in hazardous conditions.

To explore our full range and find the right chemical protection solution for your specific needs, please click here.

Understanding Tilsatec Glove Sizing and Ergonomics

Tilsatec gloves are designed to ensure that, under reasonably foreseeable conditions of use, the wearer can perform their tasks with minimal interference while receiving suitable protection. The gloves provide a close, anatomical fit in accordance with EN ISO 21420 sizing requirements. Their ergonomic design supports natural hand movement and helps reduce hand fatigue during extended use.

A properly fitting glove should:

- Follow the contours of the hand without being overly tight or loose.

- Allow free movement of the fingers and thumb without restriction.

- Maintain good contact with the skin to support tactile sensitivity and dexterity.

- Avoid excess material bunching in the palm or fingers, which may impair performance or comfort.

Factors that ensure Tilsatec gloves offer an optimal fit:

- Drop Pinky Design – This feature positions the little finger slightly lower than the other fingers, aligning with the hand’s natural resting anatomy. Since the pinky naturally sits lower and offset from the other fingers, this design improves overall ergonomics.

Our Comfort+ range predominantly incorporates this feature, enhancing dexterity and grip by allowing a more natural hand closure. This is especially beneficial for users performing repetitive tool work or working extended shifts, where comfort and reduced fatigue are essential.

- Reinforced Thumb Crotch – This refers to the area at the base of the thumb and index finger, which is strengthened with extra material or padding. This reinforcement not only prolongs the glove’s lifespan but also supports frequent pinching, flexing, and rotating movements of the thumb by providing added durability. A wide range of Tilsatec gloves feature a reinforced thumb crotch, helping the glove maintain its shape and close fit, which in turn reduces hand fatigue.

- Finger Lengths – The fingers fully reach the tips of the glove without stretching or bunching. This ensures natural hand movement and prevents any restriction of motion.

- Wrist Fit and Closure – It’s essential that the glove stays securely on the hand during use. Tilsatec offers various wrist closure options across the range, including elastic cuffs, hook-and-loop straps, and knitted wrists, to ensure a snug and comfortable fit for every wearer.

Tilsatec offers the following wrist options across the range; Elastic cuff, Hook-and-loop strap, knitted wrist to ensure the glove is well fitted to the wearer’s wrist.

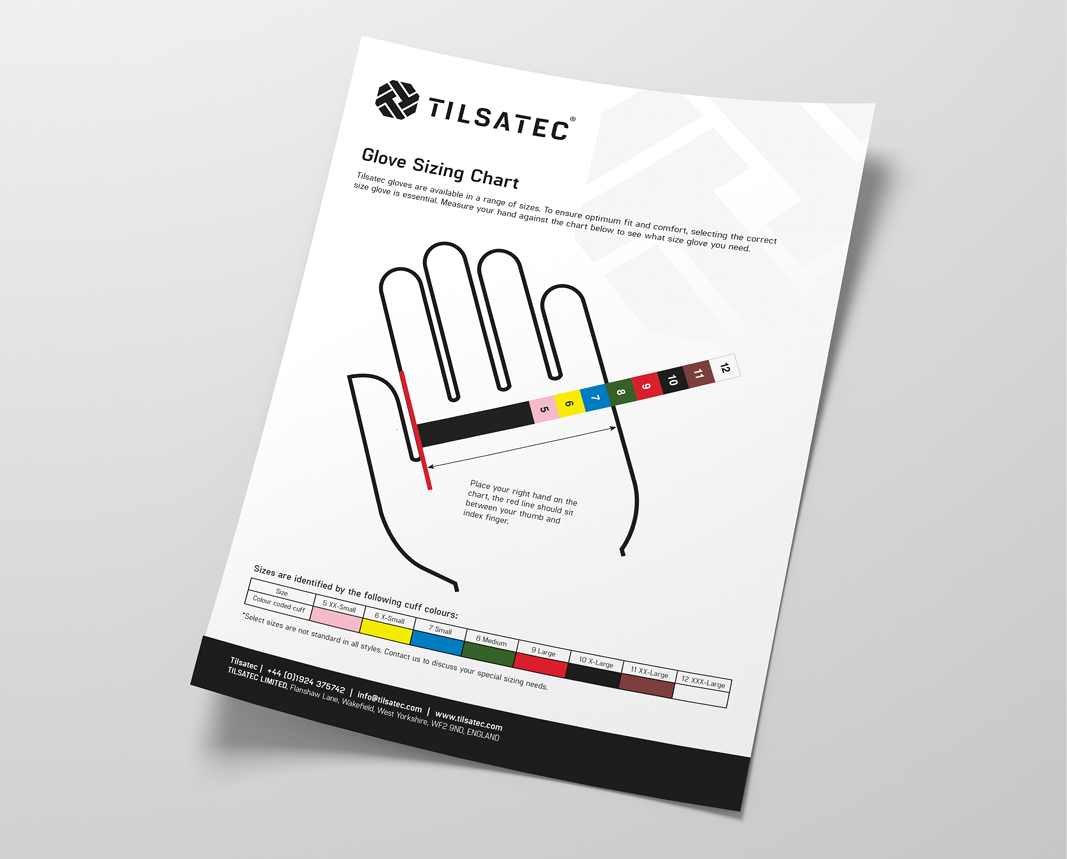

The Tilsatec glove sizing chart serves as a practical starting point for end users to identify the correct glove size, ensuring optimal fit, comfort, and performance.

We understand that hand protection is about more than just the materials used to create the glove. Our team actively works with end users on factory floors, engage one-on-one with health and safety managers across various industries, and strive to understand the real-world challenges they face concerning hand protection. We meticulously trial gloves in the field, taking on board invaluable feedback to ensure that we build and curate a portfolio of products that are tried, tested, and meet the dynamic demands of modern industry. The resounding call from industry is for more inclusive sizing. Hands are not uniform, and therefore, we must create gloves that vary to give every worker optimal options.

The examples above highlight the critical reality that even the most advanced protective technology is ineffective if the gloves do not fit properly. This is why we are listening intently to our customers and remain committed to developing hand protection with increasingly inclusive sizing options, leading the way as a responsible manufacturer in tackling the UK’s hand injury crisis.