Did you know that every year around 1000 accidents involve burns, and electric shocks which are reported to Health and Safety in the UK and approximately 30 of these accidents will be fatal. For this reason is it pivotal to have a deeper understanding of electrical class ratings and choose the right gloves that offer maximum protection and most importantly keep you safe while working with electrical equipment.

What are Electrical Class Ratings?

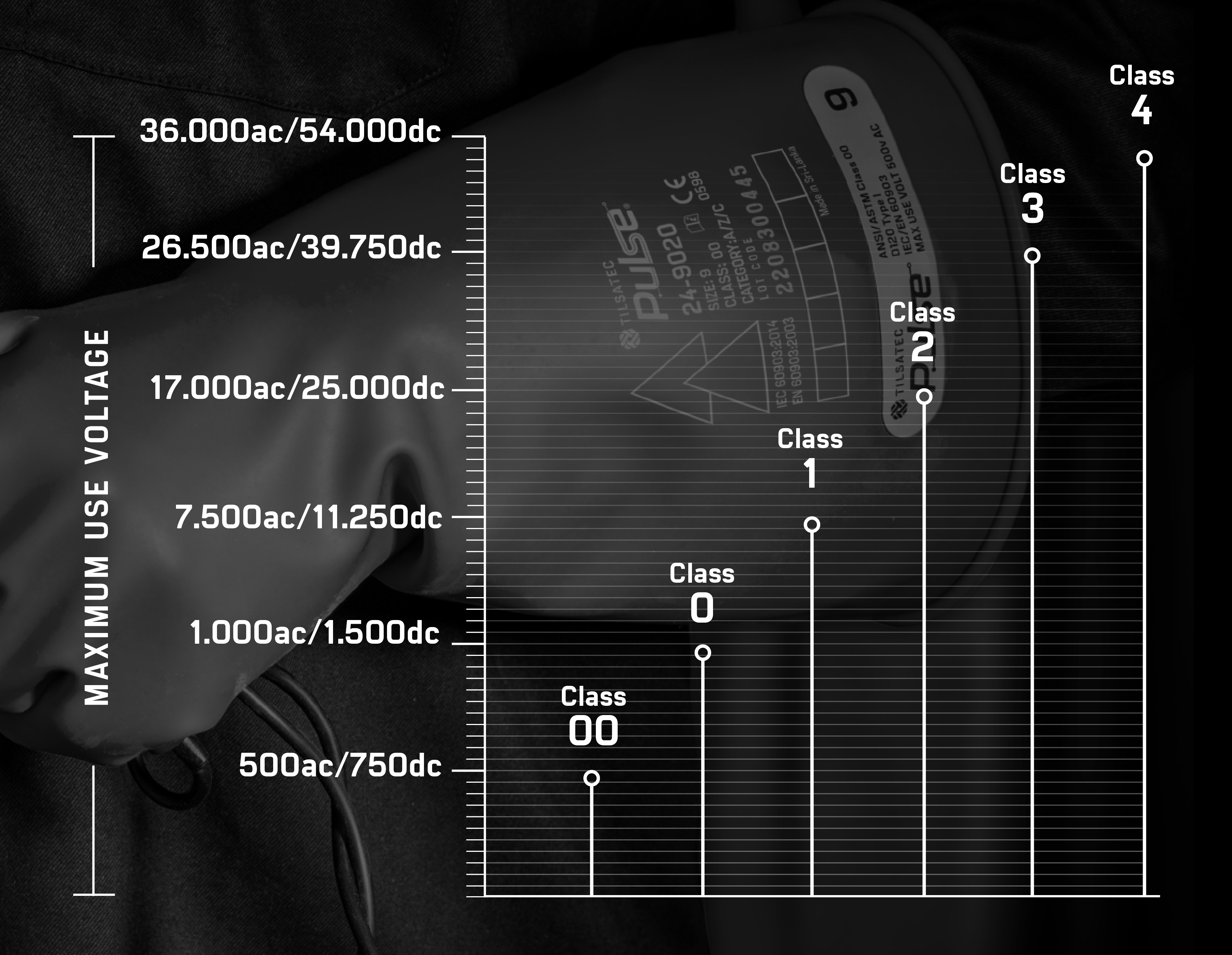

The electrical class rating is based on the glove’s ability to protect against electrical hazards. These ratings range from Class 00 to Class 4, with each class representing the maximum voltage the gloves can withstand. For example, Class 00 gloves are designed for maximum use voltage of up to 500 volts, while Class 4 gloves can handle voltages up to 36,000 volts.

Why are Electrical Class Ratings Important?

Having a clear understanding of the electrical class ratings for gloves is crucial for ensuring the safety of those in industries that work with electrical wires, machines, and cabinets. Wearing gloves with the appropriate class rating can prevent electric shocks and burns, reducing the risk of serious injury or even death. By choosing the right gloves for the role, workers can protect themselves while performing tasks such as electrical maintenance, troubleshooting, and repairs.

How to Choose the Right Gloves

Selecting the right gloves starts with assessing the voltage of the electrical equipment you’ll be working with. Once you know the maximum voltage, you can choose gloves with a corresponding class rating. It’s essential to remember that gloves should provide adequate protection with a safety margin, so always choose gloves rated higher than the voltage you expect to encounter. Another aspect of selecting the correct glove is down to the fit and feel of the glove, that is suitable for your hand, ensuring that the glove feels a snug fit but not too tight which can restrict movement.

Electrical Glove Maintenance

The integrity of electrical gloves and the protection they offer may be compromised if they are damaged or improperly maintained. It’s imperative to inspect the gloves regularly to ensure that they aren’t damaged both on the interior and exterior. The gloves should be checked for signs of wear, tear, or punctures. If any damage is observed, then it’s important to replace them to ensure the user is protected against electrical hazards.

The gloves should be stored in a clean, dry environment away from sunlight and chemicals to prevent degradation. Proper care and maintenance will extend the life of your gloves and ensure they continue to provide reliable protection.

Do Insulated Gloves Have an Expiry Date?

Electrical insulating gloves do not have an expiry date, but the gloves must comply with the period of inspection to ensure they remain fit for purpose. For gloves of class 00 and 0, a visual inspection before each use, and regular inflation tests is deemed appropriate.

How to test your insulated gloves

A visual inspection of the gloves must be carried out before use. The gloves shall be checked for nicks and tears. Close attention to potential pin pricks through the skin of the gloves is important. If there are any holes, the gloves will not provide sufficient protection and must be replaced.

To conclude, electrical gloves play a crucial role in protecting workers from electrical hazards. Understanding the class ratings and choosing the appropriate gloves for the role and industry can significantly minimise the risk of accidents and injuries caused by electrical hazards.

For more information on hand protection for electrical safety, see our Tilsatec Pulse® range of insulating gauntlets, where we provide a full-class rating of the electrical gloves and typical industry/applications.